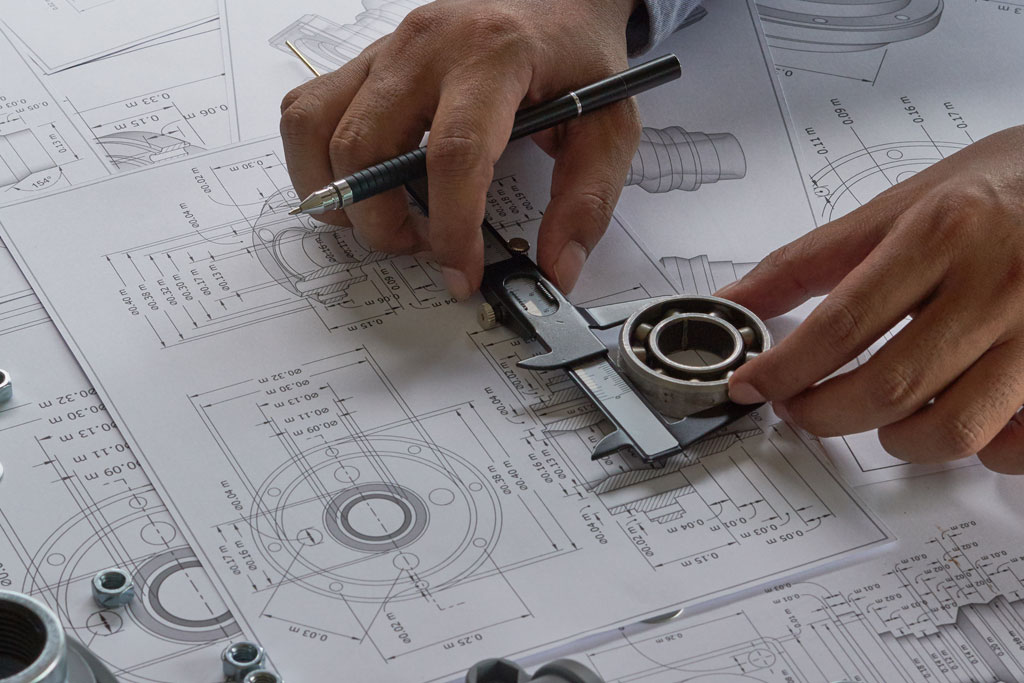

With state-of the art design capabilities and cutting-edge manufacturing technology, Mid-Plains can meet your specific needs from the smallest fabricated part to an entire turnkey system. We offer in-house engineering and design utilizing the latest in CAD systems to create accurate designs and geometric data transfer.

Your designs can be easily imported into our system by providing the CAD or dxf file via e-mail. Combined with custom nesting software and ability to stack material, we are able to increase productivity and maximize raw material usage.

Our knowledgeable staff will work with you through the research, development, engineering and fabrication of your custom manufactured equipment. We are devoted to meeting your needs with high quality products and excellent service.

Our highly skilled machinists can satisfy most of your machining needs. State-of-the-art CNC equipment allows for increased efficiency and accuracy of your critical parts.

Whether your parts require a mill or a lathe, are metal or plastic, big or small, one or many, Mid-Plains has the equipment and expertise to service your needs.

Choose a Tab below to learn more about the machinery and capabilities.

Capabilities:

Capabilities:

• 3″ through spindal

• 3400 rpm

• Rigid tapping

• Hybrid turret

Capabilities:

• 16″x30″ Bed

• High speed 12,000 rpm

• Rigid tapping

Capabilities:

• 30″x60″ Bed

• X-Axis: 60″, Y-Axis: 30″, Z-Axis: 30″

• Maximum spindle speed: 10,000 RPM

• Acer – knee mill

• Partner – knee mill

• Acra Turn – lathe

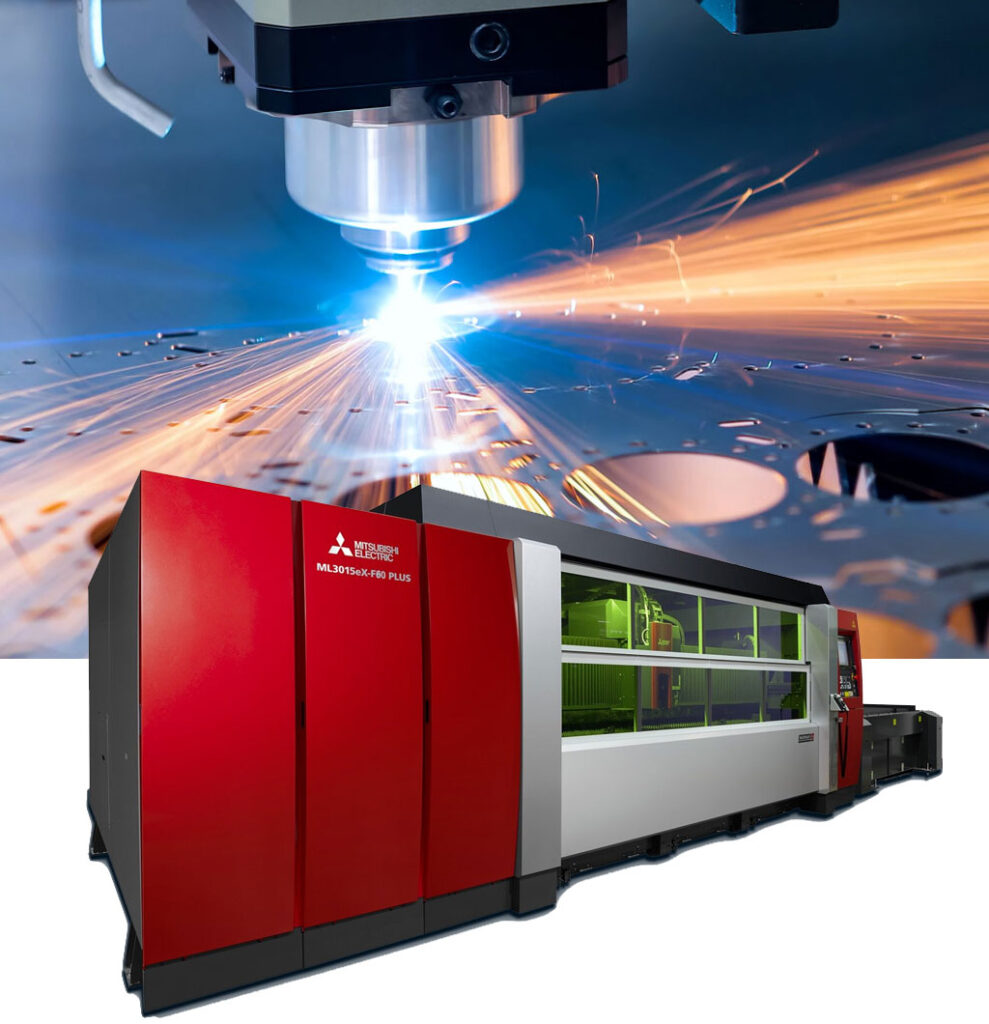

Mid-Plains Industries’ laser cutting capabilities add another dimension to the services we provide. Laser cutting is the leader in shape profiling because of its speed and accuracy.

Our Mitsubishi 3015 EXF 8,000 watt fiber laser accepts sheet sizes up to 60” x 120” and is capable of cuts up to 1″ Mild Steel and 3/4″ Stainless Steel and Aluminum.

Our laser center features automated loading/unloading, which allows quick removal of finished parts. If you require parts that fit together with precision that result in easier and quicker assembly, our laser is for you.

Abrasive water jets are ideal for tough applications such as titanium, inconel, brass, composites, aluminum, glass, stone or any other steel, including stainless.

The hair-thin water jet can quickly cut almost any material including gaskets, foams, plastics and thin rubber. Mid-Plains’ water jet cutting system offers a cutting area capacity of 60” x 120” and material thicknesses exceeding 4 inches.

In addition, water jets cut with a narrow kerf, allowing parts to be tightly nested to maximize material usage. As there is absolutely no mechanical stress, heat distortion, or heat-affected zone, the waterjet cutting system results in a higher quality product.

For machining in high volumes, short runs or prototypes, water jet cutting is the most flexible cutting tool in the world.

Calypso 50hp

Features: Diverse cutting materials: Copper, Aluminum, Rubber, Plastic, Granite, etc.

Cutting Capabilities: Up to 5″ Carbon Steel and 3″ Stainless Steel

At Mid-Plains Industries we realize not all items are efficiently cut using a waterjet or laser. Our shearing capacity of up to 1/4” by 10 feet long in mild steel and 3/16” by 10 feet long in stainless allows us to quickly cut sheet metal to size.

With the added notching station complementing our shearing process, Mid-Plains can effectively move your parts into the next stage of fabrication.

Machines:

An ever-growing assortment of dies and punches are available for both of our two-axis CNC controlled press brakes. With the flexibility of multiple bending and setup configurations, Mid-Plains can fabricate your design from large tanks to intricate electronic enclosures.

Machines:

In addition to our wide range of fabricating processes, Mid-Plains Industries is outfitted with the latest welding equipment including MIG, TIG, ARC and spot welding.

Utilizing our finishing techniques of stainless-steel polishing, bead blasting, plating and powder coating, ensures a professionally finished product to meet your specifications.

SS Finishing

Available Finishes:

Plating

Available Finishes:

Powder Coating

Various colors available

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929