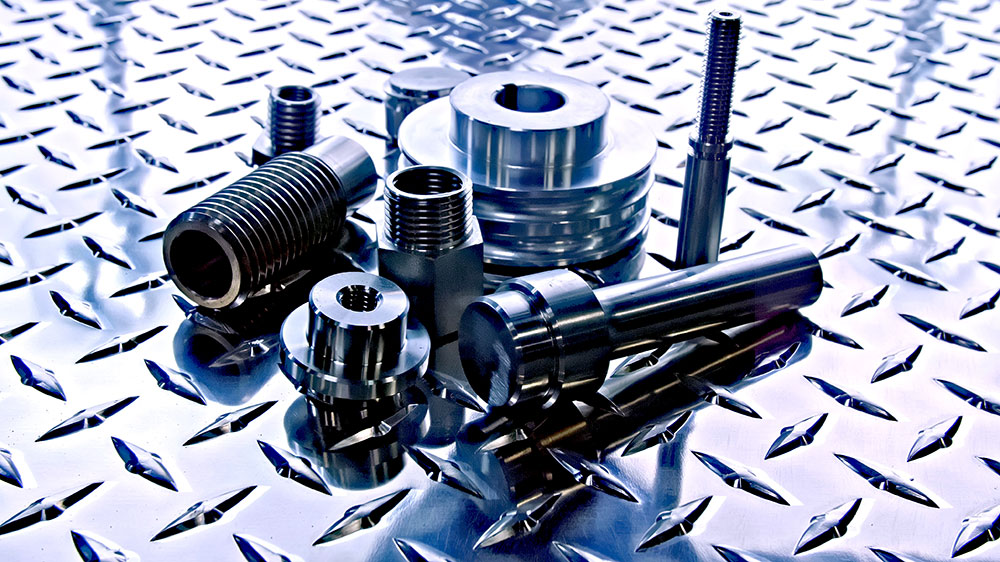

CNC machining produces parts with high precision and accuracy which has become an integral part of various industries. CNC Machining offers the advantages of efficiency and versatility when it comes to manufacturing custom parts and components.

At Mid-Plains, our highly skilled machinists can satisfy your most critical machining needs.

Whether your parts require a mill or a lathe, are metal or plastic, large or small, one or many, we have the CNC Machining equipment and expertise to service your needs.

Accuracy: CNC machining produces parts with high precision and accuracy by following exact specifications.

Versatility: CNC machines can work with different materials, such as metals, plastics and composites. They can also adapt to new designs or tasks without slowing down production.

Prototyping and Customization Capabilities: CNC machines are highly adaptable can be reprogrammed quickly to produce different parts and the ability to produce small, customized batches efficiently.

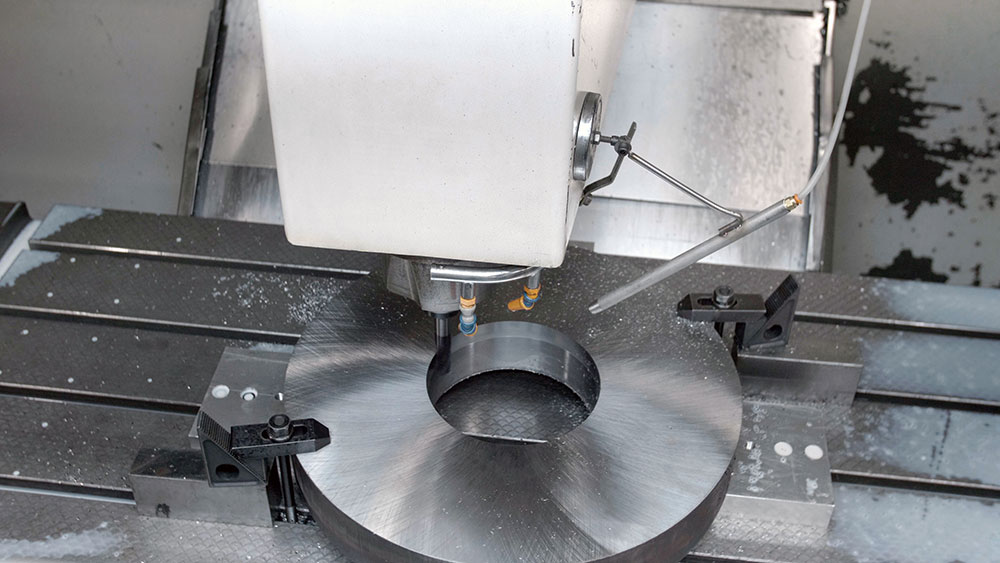

Production Speed: CNC machining can speed up production by removing the limitations of human labor.

Cost Reduction: CNC machining reduces material waste and production errors, which will lower costs for rework and scrap.

Capabilities:

Capabilities:

• 3″ through spindal

• 3400 rpm

• Rigid tapping

• Hybrid turret

Capabilities:

• 16″x30″ Bed

• High speed 12,000 rpm

• Rigid tapping

Capabilities:

• 30″x60″ Bed

• X-Axis: 60″, Y-Axis: 30″, Z-Axis: 30″

• Maximum spindle speed: 10,000 RPM

• Acer – knee mill

• Partner – knee mill

• Acra Turn – lathe

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929