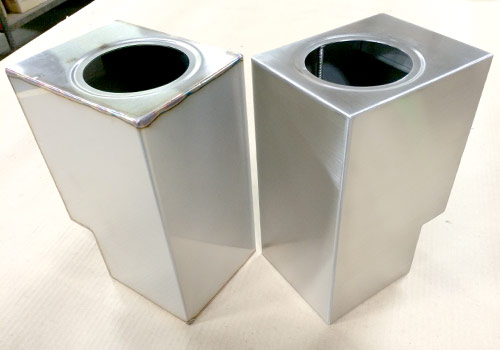

Utilizing Mid-Plains finishing techniques of stainless-steel polishing, bead blasting, plating and powder coating, ensures a professionally finished product to meet your specifications.

Finishing is the final step in the manufacturing process, where the surface of a part is altered to improve its appearance, durability, or function. Utilizing Mid-Plains diverse finishing techniques, we ensure a professionally finished product to meet your specifications.

The best finishing process for a part depends on the part’s material, the desired characteristics, and the part’s specifications.

Available Finishes:

Plating:

Powder Coating:

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929