Mid-Plains Industries laser cutting capabilities add another dimension to the manufacturing services we provide. Laser cutting is the leader in shape profiling because of its speed, accuracy, high performance and wide range of applications.

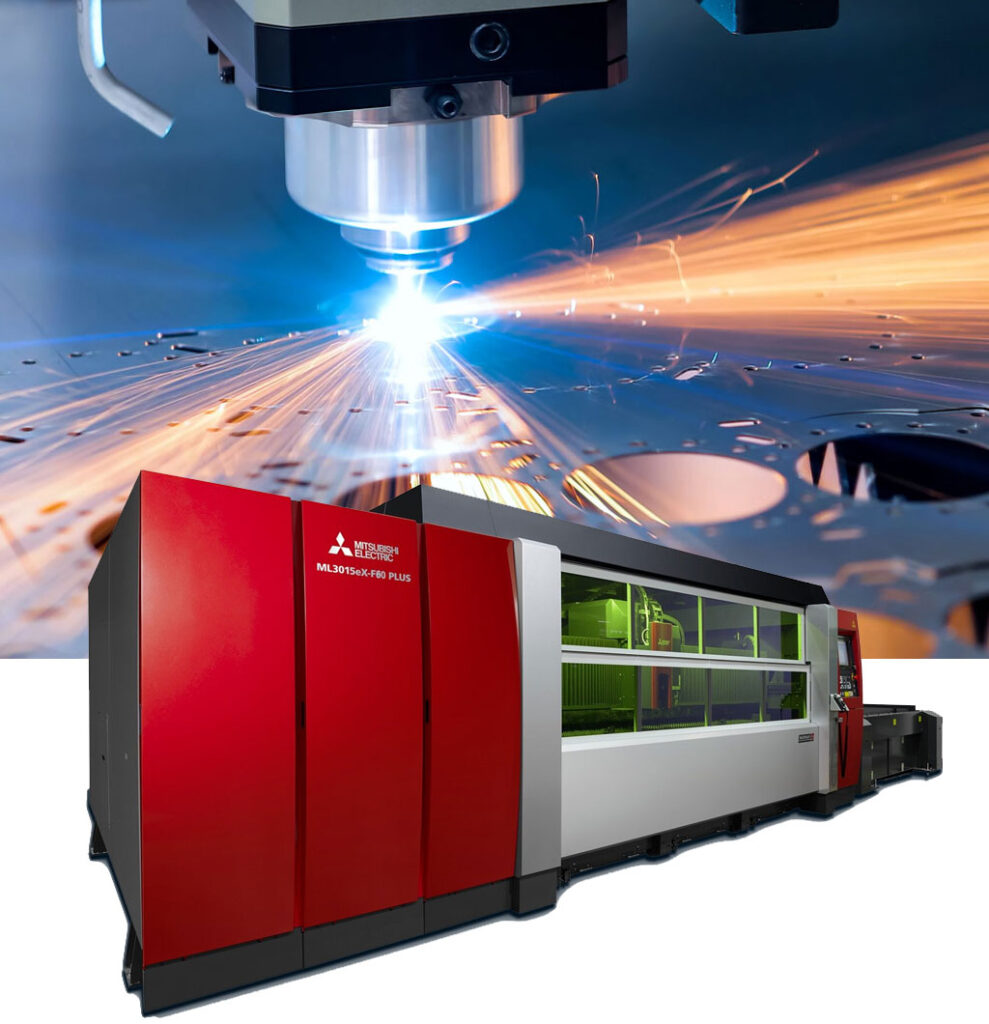

Our Mitsubishi 3015 EXF 8,000watt fiber laser accepts sheet sizes up to 60” x 120” and is capable of cuts up to 1″ Mild Steel and 3/4″ Stainless Steel and Aluminum.

Mitsubishi EXF lasers are noted for their reliable motion system and high-speed helical rack and pinion drive. This machine combines that drive system with an 8000-watt IPG fiber resonator (source) for a proven design.

Mid-Plains laser center features automated loading/unloading, which allows quick removal of finished parts. If you require parts that fit together with precision that result in easier and quicker assembly, our laser is for you.

Our laser cutting capabilities serve the Agriculture, Manufacturing, Military, Automotive and medical industries.

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929

MPI Main Line: (402) 563-6040

Sales & Service: (402) 563-6054

Order Status: (402) 563-6056

MPI Fax: (402) 563-8929